Log Products and Manufacturing

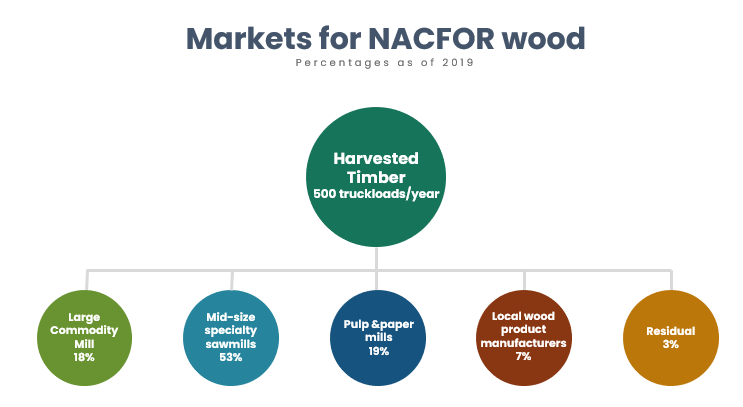

NACFOR’s operating area features a classic Kootenay mix of harvestable products. With an Allowable Annual Cut of 20,000 cubic meters, NACFOR offers a wide species mix to potential wood buyers. The open market sale of all NACFOR’s products also presents manufacturers with excellent opportunities to either start or expand operations within the Nakusp area.

A general break down of NACFOR’s annual volume by species:

- Douglas fir: 7,000 cubic meters

- Western hemlock: 5,000 cubic meters

- Western red cedar: 3,000 cubic meters

- Western larch: 3,000 cubic meters

- Other species (lodgepole pine, western white pine, interior spruce, sub-alpine fir, hardwoods): 2,000 cubic meters

Volume availability of each species will vary between cutting permits but NACFOR’s Kootenay mix timber profile usually will ensure representation of most species within each harvested area. Part of NACFOR’s mandate is to derive maximum value from each log it harvests. In order to achieve this objective, NACFOR actively promotes the sale of logs to specialty producers. The following is an example of some of the finished products that are well-matched to species and grades within NACFOR’s available timber supply.

To purchase products, contact NACFOR management.

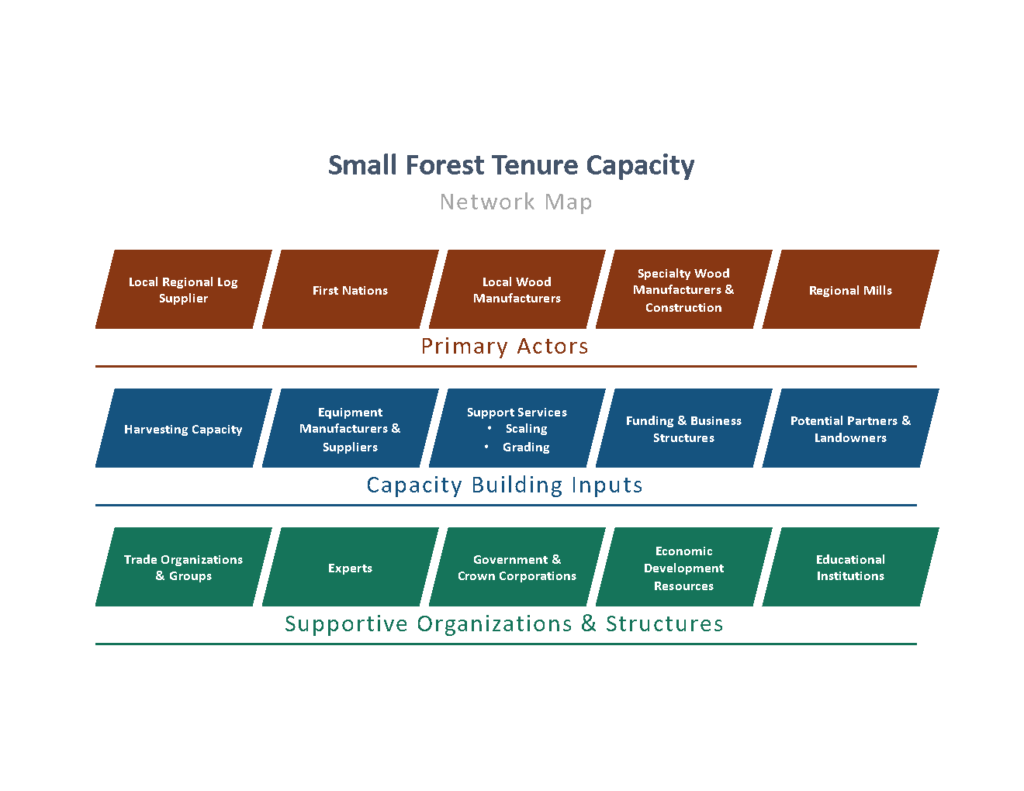

Kootenay Boundary Small Forest Tenure Capacity Building Project

Thanks to participation from woodlot owners, community forests, loggers and small wood manufacturers, valuable information about the current situation for small operators in the Kootenay Boundary is now available. We encourage you to read the May 2022 research report ‘Small Forest Tenure Capacity Building in the Kootenay Boundary’.

The report covers existing production, markets and pricing, potential timber volume, harvesting capability, employment opportunities, barriers and limitations to growth and expansion, and recommendations. A number of opportunities for strengthening capacity are emerging from the research, such as a log & information exchange, equipment training, support for business expansion, cooperative models, and more. In its next phase, the Small Forest Tenure Capacity Building project will examine the feasibility of these opportunities and pursue funding from various sources to implement feasible projects.

The report will also add credence to discussions promoting industry change. We are grateful to those who have funded this project to date: Woodlot Product Development Council (WPDC), Nakusp and Area Community Forest, Regional District of Central Kootenay-Area K, and Bell Lumber and Pole Canada. The volunteer steering committee, led by Woodlot owners Brent Petrick and Hugh Watt, continues to provide leadership.

The two research participants who won the draw for an iPad may be grateful they helped make this happen. Congratulations to Tina Marie Hesketh and Chris Choquette Enterprises Ltd.

For more information, contact: info@nakuspcommunityforest.com.

Scales and Log Yard Project

PROJECT UPDATE, September 2021:

Project update letter regarding scales and log yard from Hugh Watt, GM.

In 2020, NACFOR partnered with Mercer-Celgar Limited to develop a weigh-scale and chipping and log handling facility in Nakusp.

This project was developed to set up a log scaling, log handling, storage, accumulation, and chipping facility in Nakusp. Mercer has the other log yard locations including Castlegar, Midway, Lumby, Erie, and Okanagan Falls.

The Nakusp project has facilitated increased volume and efficiencies in fibre flow to Mercer in Castlegar and created employment and other business opportunities for the Nakusp area, including an outlet for some low-grade logs and fibre that have not been previously utilized.

Approximate annual volumes will be 60,000 to 100,000 square meters of logs going into the yard (810 logging truckloads daily) and initially about six super B-train loads going out of the yard daily to the pulp mill in Castlegar. The B-train traffic had not been incremental to the condition as the yard was moved from Lumby to Nakusp to improve transport efficiencies. The log yard and scales were also used by NACFOR for scaling and improving the merchandising of NACFOR logs.

Benefits from this project:

- New business for Nakusp community has created good jobs.

- The partnership between Mercer, the Community Forest (NACFOR) and the Village of Nakusp has offered mutual benefits.

- Geographic location of the log yard has extended the economic fibre reach for Mercer, and provides efficiencies over previous fibre transportation routes (logs and chips).

- Synergies with NACFOR and other local companies has increased potential future volumes of fibre, created opportunities, economy, and reduced waste.

- Good potential to dovetail with local Wildfire Risk Reduction efforts to utilize low value fibre more economically.

- More potential for “Full Forest Utilization” from local forestry operations within the Nakusp catchment resulting in less slash burning.

- Scaling and log yard has more easily facilitated supplying other local operators with logs.